Table of Contents

- Product Overview

- Technical Specifications & Comparative Analysis

- Industrial Applications

- Operational Guidelines

- Case Studies (2022-2024)

- Contact for Technical Consultation

N,N’-Ethylenebis(stearamide) CAS 110-30-5: Key Product Profile

Core Identification

| Parameter | Specification |

|---|---|

| Chemical Name | N,N’-Ethylenebis(stearamide) |

| CAS Registry | 110-30-5 |

| Molecular Formula | C38H76N2O2 |

| Molecular Weight | 593.03 g/mol |

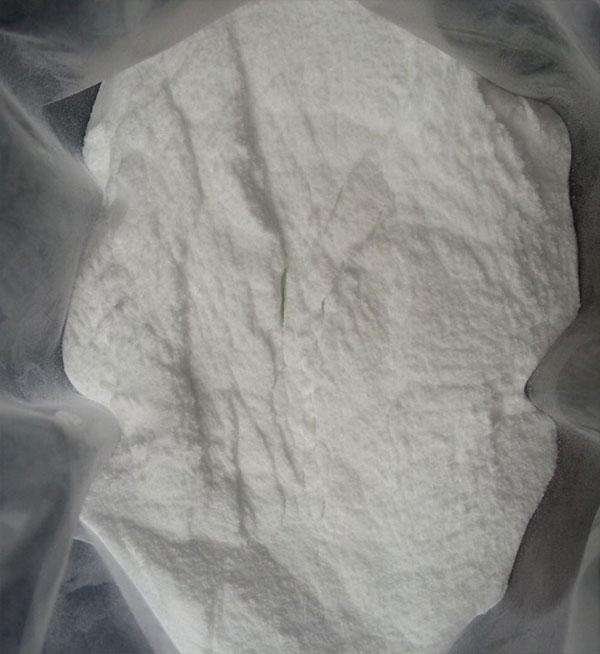

| Appearance | White to pale yellow waxy powder |

| Melting Point | 142-146°C |

| Flash Point | >200°C |

| Solubility | Insoluble in water, soluble in hot hydrocarbons |

Performance Benchmarking: EBS vs. Alternative Lubricants

| Property | EBS | Calcium Stearate | Zinc Stearate |

|---|---|---|---|

| Thermal Stability (°C) | 240 | 180 | 200 |

| Lubrication Efficiency | Excellent | Good | Moderate |

| Moisture Resistance | High | Medium | Low |

| FDA Compliance | Yes | Limited | No |

Multifunctional Applications in Polymer Engineering

Primary Functional Roles

- Internal Lubrication: Reduces melt viscosity in PVC (15-20% torque reduction)

- Mold Release Agent: Enables clean demolding in injection processes

- Anti-blocking Agent:

Prevents film adhesion in LDPE packaging

- Flow Promoter:

Enhances processing rates in engineering plastics

Sector-specific Implementations

| Industry | Typical Dosage | Performance Benefit |

|---|---|---|

| Automotive Plastics | 0.3-0.8% | 25% faster cycle times |

| Wire & Cable | 0.5-1.2% | 30% improved surface smoothness |

| Masterbatches | 1.0-1.5% | Enhanced pigment dispersion |

Optimal Processing Parameters

Recommended Incorporation Methods

- Dry Blending: Premix with polymer pellets before extrusion

- Melt Compounding: Introduce during twin-screw processing

- Solution Blending: For specialty coating applications

Temperature Guidelines

| Process | Optimal Range | Maximum Exposure |

|---|---|---|

| Injection Molding | 180-220°C | 240°C |

| Film Extrusion | 160-200°C | 230°C |

Documented Success Cases (2023-2024)

Case 1: Automotive Bumper Production

Client: Tier-1 German auto supplier

Challenge: Flow marks in PP bumpers

Solution: 0.6% EBS addition

Result: 18% scrap reduction, surface Ra improved from 2.1μm to 0.8μm

Case 2: High-Speed Cable Extrusion

Client: Japanese cable manufacturer

Challenge: Die buildup in XLPE insulation

Solution: 1.0% EBS masterbatch

Result: 40% longer continuous run times

Technical Partnership Opportunities

Request formulation guidance or material samples:

Email: info@vivalr.com

Tel: (86) 15866781826

评论

目前还没有评论。