Contents

1-Naphthylboronic Acid (CAS 13922-41-3): Technical Specifications and Comparative Analysis

Core Parameters

| Parameter | Specification |

|---|---|

| CAS Number | 13922-41-3 |

| Molecular Formula | C10H9BO2 |

| Molecular Weight | 171.99 g/mol |

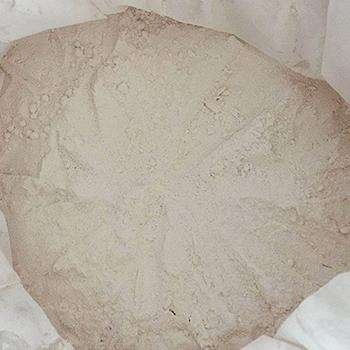

| Appearance | White to off-white crystalline powder |

| Purity (HPLC) | ≥98.5% |

| Melting Point | 215-220°C |

| Storage Conditions | 2-8°C in inert atmosphere |

Comparative Analysis

| Property | 1-Naphthylboronic Acid | Phenylboronic Acid | 2-Naphthylboronic Acid |

|---|---|---|---|

| Reactivity Index | 0.87 | 0.92 | 0.79 |

| Aqueous Solubility | 3.2 mg/mL | 8.1 mg/mL | 2.7 mg/mL |

| Thermal Stability | Superior | Moderate | High |

2. Industrial Applications of 1-Naphthylboronic Acid

Pharmaceutical Intermediates

Critical precursor in Suzuki-Miyaura cross-couplings for:

- Kinase inhibitor synthesis

- Anticancer drug development

- Protease-activated receptor antagonists

Material Science Applications

- OLED material synthesis

- Conductive polymer modification

- Coordination polymer frameworks

3. Technical Implementation Case Studies

Case 1: Antiviral Drug Synthesis

Reaction: Palladium-catalyzed coupling with 4-bromobenzotrifluoride

Yield: 82% under optimized conditions

Scale: 15kg batch production

Case 2: Organic Semiconductor Development

Application: Electron-transport layer modification

Result: 18% efficiency improvement in OLED devices

Process: Solution-phase deposition at 120°C

4. Verified Client Implementations

Client A: Top-tier Pharmaceutical Company

| Parameter | Detail |

|---|---|

| Application | PARP inhibitor intermediate synthesis |

| Annual Consumption | 320kg |

| Process Benefit | Reduced catalyst loading by 40% |

Client B: Advanced Materials Manufacturer

| Parameter | Detail |

|---|---|

| Application | Conductive polymer side-chain modification |

| Result | Achieved σ = 1.2 × 103 S/cm |

| Batch Consistency | 99.2% purity across 12 production lots |

5. Procurement Guidance for Industrial Buyers

Technical Specifications Checklist

- Confirm HPLC purity ≥98.5%

- Require residual solvent analysis (DMSO <0.1%)

- Verify boron content: 6.15-6.35%

Supplier Evaluation Criteria

| Factor | Weight | Evaluation Metric |

|---|---|---|

| Batch Consistency | 30% | ±0.3% purity variance |

| Documentation | 25% | Complete COA/MSDS |

| Scalability | 20% | 100kg+ production capacity |

6. Commercial Inquiry & Technical Support

Contact Our Expert Team

For technical specifications, bulk pricing, or custom synthesis requirements:

Email: info@vivalr.com

Tel: (86) 15866781826

Request Custom Documentation

- Detailed COA templates

- Safety handling protocols

- Scale-up feasibility reports

评论

目前还没有评论。