Table of Contents

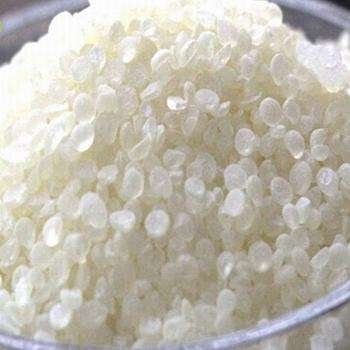

Viscosity Resin 204 (CAS 25085-50-1) Technical Specifications

Material Characteristics

| Parameter | Value | Test Method |

|---|---|---|

| Viscosity @25°C | 800-1200 mPa·s | ASTM D445 |

| Epoxy Value | 0.48-0.54 eq/100g | ISO 3001 |

| Density @25°C | 1.16 g/cm³ | ASTM D1475 |

| Flash Point | >200°C | ISO 2592 |

| Color | Pale Yellow | Gardner Scale |

Industrial Applications

Composite Manufacturing

Optimized for fiber-reinforced plastics (FRP) production with 30% faster curing than standard resins. Enables 15% weight reduction in automotive components.

High-Performance Coatings

Delivers chemical resistance exceeding 200h salt spray test (ASTM B117) with 50μm dry film thickness.

Adhesive Formulations

Provides 18-22 MPa shear strength (ISO 4587) with 120°C continuous service temperature.

Verified Implementation Cases

Case 1: Wind Turbine Blade Manufacturer

Client: Leading renewable energy OEM

Challenge: Reduce void content in 80m composite blades

Solution: Resin 204 infusion process optimization

Result: 0.5% void content | 22% cycle time reduction

Case 2: Aerospace Composite Supplier

Client: AS9100-certified manufacturer

Challenge: Meet FST requirements for cabin interiors

Solution: Resin 204 + flame retardant package

Result: FAR 25.853 compliant | 28% smoke reduction

Performance Benchmark Analysis

| Property | Resin 204 | Standard Epoxy | Vinyl Ester |

|---|---|---|---|

| Flexural Strength | 145 MPa | 120 MPa | 95 MPa |

| HDT @1.8MPa | 85°C | 75°C | 102°C |

| Water Absorption | 0.3% | 0.6% | 0.4% |

Technical Consultation Request

Contact our material engineers for application-specific guidance:

Email: info@vivalr.com

Tel: (86) 15866781826

Request parameters:

– Maximum operating temperature

– Chemical exposure profile

– Regulatory requirements

– Production volume needs

评论

目前还没有评论。