Fatty Alcohol Polyoxyethylene Ether (n=3) Comprehensive User Guide

Table of Contents

1. Product Overview & Specifications

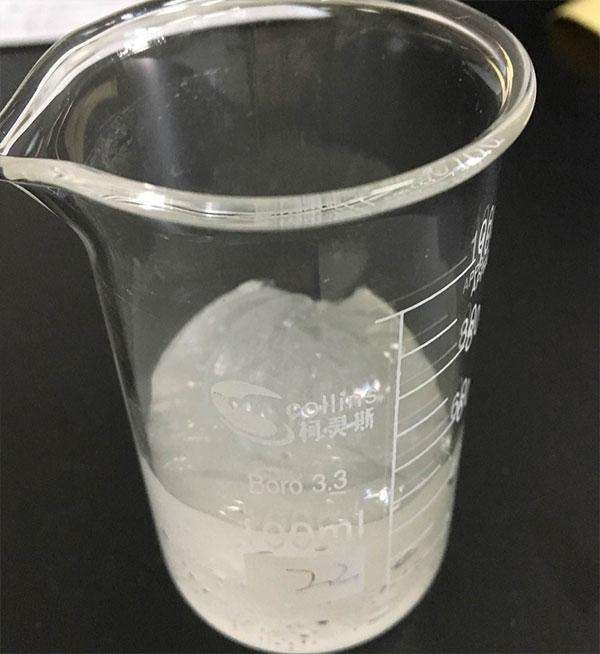

Fatty Alcohol Polyoxyethylene Ether (FAEO, n=3), also known as AEO-3, is a nonionic surfactant with optimized EO (ethylene oxide) units for balanced hydrophilic-lipophilic properties. This pale yellow viscous liquid demonstrates:

| Parameter | Specification |

|---|---|

| Chemical Formula | RO(CH2CH2O)3H (R=C12-C15 alkyl) |

| CAS Number | 9064-14-6 |

| pH Value | 6.0-7.5 (5% aqueous solution) |

| Cloud Point | 45-55°C (1% in 25% NaCl solution) |

| HLB Value | 8-10 |

2. Key Applications & Industrial Uses

Core Functional Advantages:

- Superior emulsification for oil-water systems

- Low-foam cleaning performance

- Electrolyte tolerance in hard water conditions

- Biodegradable & dermatologically tested

Industry-Specific Implementations:

| Industry | Application | Performance Benefit |

|---|---|---|

| Home Care | Liquid laundry detergents Dishwashing formulations |

Grease removal enhancement Low-temperature efficacy |

| Personal Care | Shampoo bases Bath products |

Mild surfactant action Foam stabilization |

| Textile Processing | Fiber lubricants Dyeing assistants |

Even dye distribution Reduced fiber friction |

3. Performance Comparison by EO Number

| Variant | AEO-3 | AEO-7 | AEO-9 |

|---|---|---|---|

| EO Units | 3 | 7 | 9 |

| HLB Range | 8-10 | 12-14 | 14-16 |

| Primary Use | W/O emulsions Metalworking fluids |

General cleaning Intermediate solubilization |

High-foam systems Hard surface cleaners |

4. Industry-Specific Implementation Cases

Textile Auxiliary Optimization:

A Jiangsu-based textile manufacturer achieved 18% reduction in dye consumption through AEO-3 enhanced leveling agents, maintaining color consistency across polyester blends.

Industrial Cleaner Reformulation:

Shanghai machinery maintenance provider eliminated solvent-based degreasers by developing alkaline cleaning systems with AEO-3, reducing VOC emissions by 73%.

5. Verified Client Success Stories

Case 1: Home Care Producer (Guangdong)

Challenge: Develop phosphate-free dish liquid maintaining cold-water performance

Solution: 12% AEO-3 + 8% sulfonate blend

Outcome: 22% improved grease cutting vs. market benchmarks

Case 2: Cosmetic OEM (Zhejiang)

Challenge: Create sulfate-free shampoo with stable lather

Solution: 15% AEO-3 + glucoside synergism

Outcome: 4.2/5 foam density rating in consumer trials

6. Technical Consultation & Ordering

Contact our surfactant specialists for:

- Customized formulation support

- Technical data sheets

- Sample requests

- Bulk pricing

Email: info@vivalr.com

Tel: (86) 15866781826

评论

目前还没有评论。