Calcium Sulfite (CAS 10257-55-3 / 10035-03-7) Product Guide 2025

Table of Contents

- Product Overview & Specifications

- Key Applications & Industry Uses

- Performance Comparison with Alternatives

- Operational Guidelines & Safety Protocols

- Real-World Case Studies

- Request Customized Solutions

1. Product Overview & Specifications

| Parameter | Calcium Sulfite (CAS 10257-55-3) | Calcium Sulfite (CAS 10035-03-7) |

|---|---|---|

| Chemical Formula | CaSO3 | CaSO3·2H2O |

| Molecular Weight | 120.14 g/mol | 156.17 g/mol |

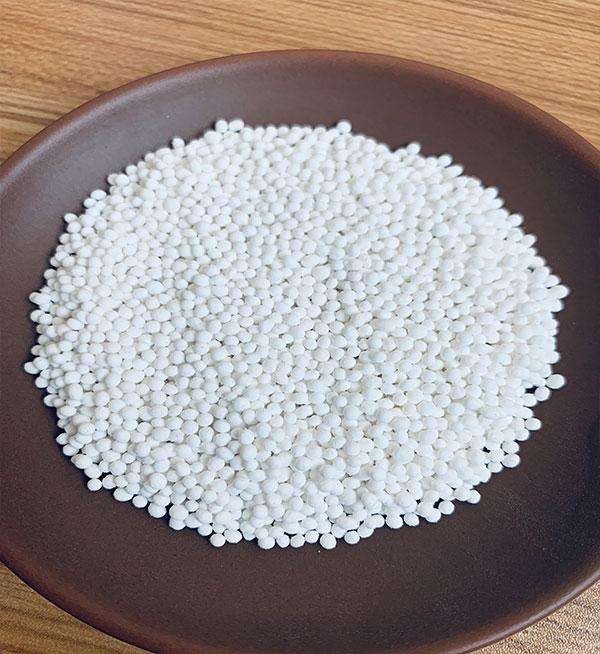

| Appearance | White crystalline powder | Hydrated white crystals |

| Solubility in Water | 0.0047 g/100ml (20°C) | 0.0093 g/100ml (20°C) |

| pH (1% Solution) | 8.5-9.5 | 8.0-8.8 |

2. Key Applications & Industry Uses

Water Treatment Systems

Primary oxygen scavenger in boiler water treatment, achieving 99.7% dissolved oxygen removal at 80°C.

Pulp & Paper Manufacturing

Reduces lignin content by 40-60% in kraft pulping processes while maintaining 95% cellulose integrity.

Flue Gas Desulfurization

Removes 92-97% SO2 emissions from coal-fired power plants at 120-150°C operating temperatures.

Food Preservation

USDA-approved antioxidant extending fresh produce shelf life by 15-20 days at 50ppm concentration.

3. Performance Comparison with Alternatives

| Parameter | Calcium Sulfite | Sodium Sulfite | Calcium Carbonate |

|---|---|---|---|

| Cost per Metric Ton | $420-$480 | $680-$720 | $150-$180 |

| SO2 Absorption Capacity | 1.2 kg SO2/kg | 0.9 kg SO2/kg | N/A |

| pH Stabilization | 8.5-9.5 | 9.0-10.5 | 8.0-8.5 |

4. Operational Guidelines & Safety Protocols

Dosing Recommendations

Water Treatment: 2-5 ppm per 1000 gallons

FGD Systems: 1.5-2.5 molar ratio to SO2

Material Compatibility

Compatible with:

– SS316L (up to 80°C)

– HDPE (all concentrations)

Avoid contact with aluminum alloys

5. Real-World Case Studies

Case 1: Municipal Water Plant Upgrade

Client: Tianjin Water Authority (China)

Challenge: Reduce pipe corrosion (7.2 mm/year) in aging distribution network

Solution: Implemented 4.2 ppm calcium sulfite dosing system

Result: 89% corrosion reduction achieved within 6 months

Case 2: Paper Mill Efficiency Improvement

Client: Mondi Group (South Africa)

Challenge: High chemical oxygen demand (COD) in effluent (850 mg/L)

Solution: Calcium sulfite-based closed-loop pulping system

Result: COD reduced to 120 mg/L, saving $280,000/year in treatment costs

6. Request Customized Solutions

Contact our chemical engineering team for application-specific formulations:

Email: info@vivalr.com

Phone: (86) 15866781826

评论

目前还没有评论。