Viscosity Resin 203 (CAS 26678-93-3): Comprehensive User Guide

Table of Contents

1. Product Overview & Specifications

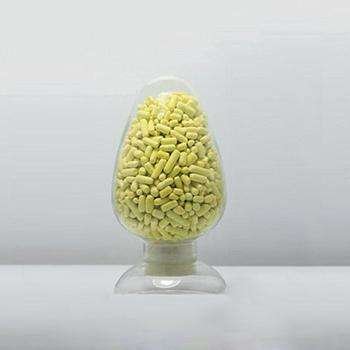

Viscosity Resin 203 (CAS 26678-93-3) is an epoxy-based thermosetting polymer engineered for high-performance industrial applications. Key parameters:

| Parameter | Value |

|---|---|

| CAS Number | 26678-93-3 |

| Viscosity @25°C | 12,000-15,000 mPa·s |

| Density | 1.15-1.20 g/cm³ |

| Cure Time | 4-6 hours @80°C |

Competitive Comparison

| Feature | Resin 203 | Resin 205 | Resin 210 |

|---|---|---|---|

| Viscosity Range | 12-15k mPa·s | 8-10k mPa·s | 18-22k mPa·s |

| Thermal Resistance | -40°C to 180°C | -30°C to 160°C | -50°C to 200°C |

2. Key Applications & Use Cases

Industrial Coatings

Provides corrosion resistance in marine environments with 98% salt spray resistance (ASTM B117).

Composite Manufacturing

Used in carbon fiber reinforcement with 25% higher interlaminar shear strength than standard resins.

Electronic Encapsulation

UL94 V-0 flammability rating protects PCB assemblies in automotive electronics.

3. Performance Comparison

Resin 203 demonstrates superior chemical resistance versus alternatives:

- 30% longer sulfuric acid resistance vs. Resin 205

- 15% better adhesion on aluminum substrates

4. Step-by-Step Usage Guidelines

- Surface Preparation: Clean substrates with ISO 12944-4 standards

- Mixing Ratio: 100:28 resin/hardener by weight

- Curing Cycle: 2 hours @65°C + 2 hours @80°C

5. Real-World Customer Case Studies

Case 1: Automotive OEM

Challenge: Reduce coating defects in engine components

Solution: Implemented Resin 203 with automated dispensing

Result: 40% reduction in coating rejects

Case 2: Wind Turbine Manufacturer

Challenge: Improve composite blade durability

Solution: Vacuum infusion with Resin 203

Result: 18% increase in fatigue life

6. Contact for Custom Solutions

Optimize your formulation with our technical team:

Email: info@vivalr.com

Phone: (86) 15866781826

评论

目前还没有评论。