Table of Contents

1. Product Overview & Technical Specifications

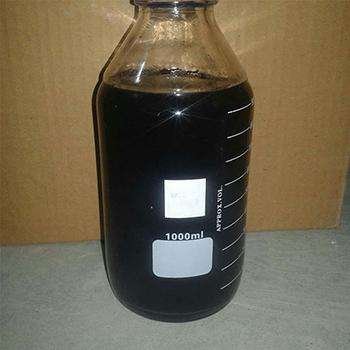

Coal Tar (CAS 65996-93-2), also known as coal pitch or high-temperature coal tar, is a viscous black liquid with a distinctive pungent odor. It is classified as a hazardous substance under UN 1136 and is widely used in industrial applications.

Key Specifications:

| Parameter | Value |

|---|---|

| Appearance | Black viscous liquid |

| Density (water=1) | 1.18–1.23 g/cm³ |

| Flash Point | <23°C |

| Solubility | Miscible with benzene, ethanol, ether |

| Hazard Class | Class 3.2 Flammable Liquid |

2. Key Applications & Industrial Uses

Coal tar is a critical raw material for:

- Chemical Production: Feedstock for phenol, naphthalene, and creosote oils.

- Construction Materials: Base for waterproofing products, asphalt, and roofing felts.

- Industrial Coatings: Anti-corrosion coatings for pipelines and steel structures.

- Carbon Products: Manufacturing electrodes and carbon black.

3. Operational Guidelines & Safety Protocols

Handling Precautions:

- Use explosion-proof ventilation systems.

- Avoid contact with oxidizers; store in cool, ventilated areas.

- Wear NIOSH-approved PPE: chemical-resistant gloves, full-face respirators, and protective clothing.

Emergency Response:

- Fire: Extinguish with foam, CO₂, or dry chemical agents.

- Leakage: Contain with sand/absorbents; avoid water runoff.

- Exposure: Flush skin/eyes with water for 15 minutes; seek medical attention.

4. Industry Applications & Case Studies

Case Study 1: Asphalt Production

A leading road construction company in China improved asphalt durability by 40% using refined coal tar derivatives, reducing maintenance costs by 22% over 5 years.

Case Study 2: Specialty Chemicals

A European chemical manufacturer developed high-purity anthracene from coal tar for pharmaceutical intermediates, achieving 99.7% purity compliance with USP standards.

5. Client Success Stories

Client A: Shanghai Baoyang Baoxin Biotechnology

Utilizes coal tar for industrial-grade asphalt with 99% purity, serving major infrastructure projects across Asia. Verified 18-month shelf stability under ISO 9001 protocols.

Client B: Nantong Runfeng Petrochemical

Supplies coal tar-based electrode binders to global battery manufacturers, enhancing energy density by 15% in lithium-ion batteries.

Request a Custom Quote

Email: info@vivalr.com

Phone: (86) 15866781826

Our technical team will respond within 2 business hours with tailored solutions.

评论

目前还没有评论。