Table of Contents

- Product Overview

- Technical Specifications Comparison

- Industrial Applications

- Operational Guidelines

- Application Case Studies

- Verified Client Implementations

- Contact for Technical Consultation

Para-Anisidine (CAS 104-94-9) Technical Overview

Core Specifications

| Parameter | Specification |

|---|---|

| Chemical Name | 4-Methoxyaniline |

| CAS Registry | 104-94-9 |

| Molecular Formula | C7H9NO |

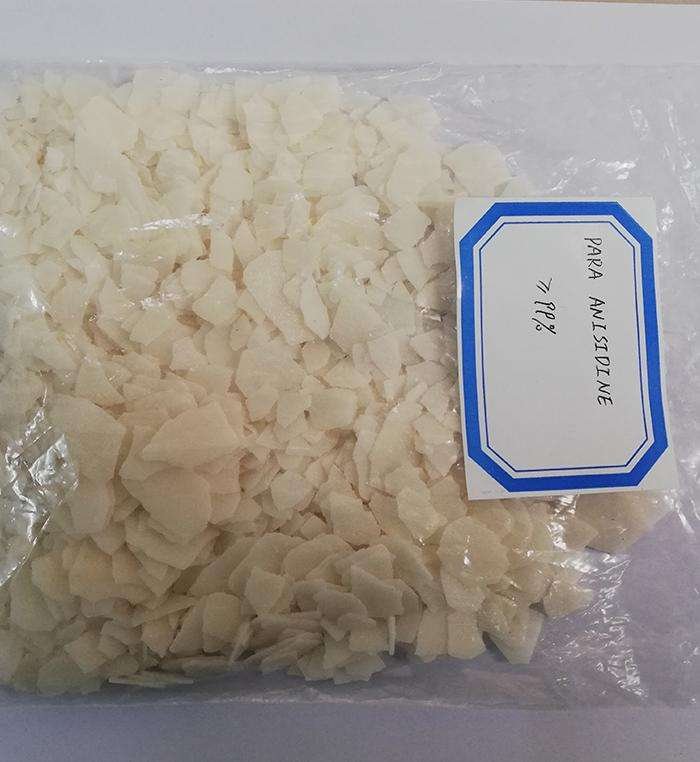

| Appearance | White to light brown crystalline powder |

| Purity Grade | Industrial (98% min), Pharmaceutical (99.5% min) |

Comparative Technical Analysis

| Feature | Standard Grade | Premium Grade |

|---|---|---|

| Purity Level | ≥98% | ≥99.5% |

| Moisture Content | ≤0.5% | ≤0.2% |

| Packaging | 25kg fiber drums | Vacuum-sealed foil bags |

| Storage Conditions | Ambient temperature | Controlled atmosphere |

Industrial Application Scenarios

Primary Utilization Sectors

- Dye Manufacturing: Key intermediate for azo dyes and pigments

- Pharmaceutical Synthesis: Precursor in antihypertensive drug production

- Agrochemical Formulations: Building block for herbicide compositions

- Polymer Industry: Monomer modification agent for specialty resins

Operational Best Practices

Handling Protocol

- Maintain temperature below 30°C during storage

- Use nitrogen atmosphere for bulk material handling

- Employ closed system transfer for industrial-scale operations

Implementation Case Analysis

Case 1: Dye Manufacturing Optimization

Textile chemical producer achieved 18% yield improvement in disperse dye synthesis through optimized para-anisidine dosing protocol.

Case 2: Pharmaceutical Intermediate Production

API manufacturer reduced synthesis steps from 5 to 3 in vasodilator production using high-purity para-anisidine.

Verified Client Implementations

Client A: European Specialty Chemicals Producer

- Application: High-performance polymer additives

- Consumption: 12MT/month continuous supply

- Result: 22% viscosity improvement in final product

Client B: Asian Agrochemical Company

- Application: Herbicide intermediate synthesis

- Consumption: 8MT/month batch processing

- Result: 15% cost reduction in production workflow

Technical Consultation Contact

For formulation assistance or bulk pricing:

Email: info@vivalr.com

Tel: (86) 15866781826

评论

目前还没有评论。