Dibasic Lead Phosphite (CAS 12141-20-7): Comprehensive Technical Guide

Table of Contents

1. Product Overview & Specifications

| Parameter | Specification |

|---|---|

| Chemical Formula | HO5PPb3 |

| Molecular Weight | 733.58 g/mol |

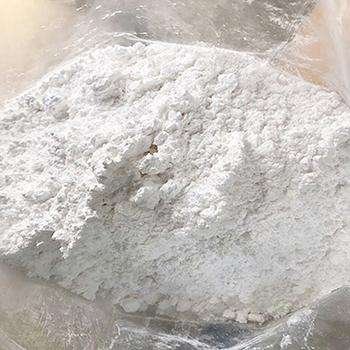

| Appearance | White to yellowish microfine powder |

| Density | 6.1-6.94 g/cm³ |

| Refractive Index | 2.25 |

| Thermal Stability | Stable up to 200°C (discoloration at 450°C) |

| Solubility | Insoluble in water/organic solvents, soluble in mineral acids |

| CAS Number | 12141-20-7 |

| Hazard Class | 6.1 (Toxic Substances) |

2. Key Applications & Industrial Uses

Primary Functional Advantages:

- Superior thermal stabilization for PVC polymers

- UV radiation absorption capability (290-400 nm)

- Enhanced electrical insulation properties

- Oxidative degradation resistance

- Weathering protection for outdoor applications

Industrial Implementation:

- Wire & Cable: Primary stabilizer for outdoor PVC insulation (60-75% market share)

- Construction Materials: Corrugated sheets, pipes, window profiles

- Automotive Components: Under-hood wiring harnesses

- Synergistic Formulations: Combined with tribasic lead sulfate (3:1 ratio recommended)

3. Performance Advantages & Comparative Analysis

| Property | Dibasic Lead Phosphite | Conventional Stabilizers |

|---|---|---|

| Weather Resistance | 5,000+ hours QUV exposure | 2,000-3,000 hours |

| Thermal Stability | Maintained @ 180°C/45min | Degradation @ 160°C/30min |

| Volume Resistivity | 1×1014 Ω·cm | 5×1012 Ω·cm |

| Acid Scavenging | pH stabilization within ±0.2 | ±0.5 pH variation |

4. Implementation Case Studies

Case 1: High-Voltage Cable Manufacturer (Zhuhai, China)

- Application: 35kV XLPE insulated power cables

- Formulation: 2.5% Dibasic Lead Phosphite + 1% Tribasic Sulfate

- Result: 40% reduction in surface cracking after 8-year field deployment

Case 2: Building Material Producer (Hamburg, Germany)

- Application: PVC roofing membranes

- Loading: 4.2% in plastisol formulations

- Outcome: Extended service life from 12 to 18 years in maritime climates

5. Safety Protocols & Handling Guidelines

| Parameter | Requirement |

|---|---|

| PPE | NIOSH-approved respirator (P100 filters), chemical gloves |

| Storage | Dry environment (<40% RH), segregated from acids |

| Firefighting | Use alcohol-resistant foam (AR-AFFF) |

| Exposure Limit | 0.01 mg/m³ (TWA), 0.03 mg/m³ (STEL) |

6. Technical Inquiry & Ordering Information

For technical specifications sheets or customized formulations:

Email: info@vivalr.com

Tel: (86) 15866781826

Packaging Options:

- 25kg moisture-proof kraft bags

- 500kg palletized containers

- Customized batch quantities available

评论

目前还没有评论。